Artificial Intelligence Cuts Down Amazons Packaging Issues

Artificial intelligence cuts down packaging issues for amazon – Artificial Intelligence Cuts Down Amazon’s Packaging Issues – that’s a headline that grabs you, right? We all know Amazon’s a giant, and that giant generates a

-lot* of packaging waste. Think mountains of cardboard, plastic, and bubble wrap. This isn’t just an environmental problem; it’s a huge economic one too. But what if I told you AI is stepping in to help solve this massive challenge?

This post dives into how artificial intelligence is revolutionizing Amazon’s packaging, making it more sustainable and efficient.

From optimizing box sizes based on product dimensions to streamlining warehouse logistics, AI is proving to be a game-changer. We’ll explore how machine learning algorithms predict the perfect packaging for each item, minimizing waste and maximizing protection. We’ll also look at the potential cost savings, environmental benefits, and the challenges involved in implementing these AI-powered solutions. Get ready to unpack the future of sustainable e-commerce!

Amazon’s Packaging Problem: Artificial Intelligence Cuts Down Packaging Issues For Amazon

Amazon’s massive scale translates to a massive packaging problem. The sheer volume of goods shipped daily generates an enormous amount of waste, impacting the environment and raising consumer concerns. Understanding the scope of this issue is crucial to developing effective solutions.

The Scale of Amazon’s Packaging Waste

The exact figures on Amazon’s packaging waste are not publicly released, but various reports and studies paint a concerning picture. Millions of packages are shipped daily, utilizing a mix of materials including cardboard, plastic films (bubble wrap, air pillows), paper fillers, and tape. Disposal methods vary, with much ending up in landfills, contributing to greenhouse gas emissions and environmental pollution.

The sheer volume of cardboard alone is staggering, and the plastic components often prove difficult to recycle effectively. This massive waste stream poses a significant challenge for both Amazon and the environment.

Environmental and Economic Impacts

The environmental impact is multifaceted. Landfill space is consumed, contributing to habitat destruction. The manufacturing process of packaging materials consumes significant energy and resources. Furthermore, the decomposition of certain materials releases harmful greenhouse gases. Economically, the cost of packaging materials, disposal, and potential fines or penalties for non-compliance with environmental regulations represents a significant expense for Amazon.

The company’s efforts to reduce its environmental footprint are directly tied to its financial bottom line. Moreover, negative publicity surrounding excessive packaging can damage the company’s brand image and customer loyalty.

Consumer Complaints and Concerns

Consumers frequently complain about excessive packaging. Many report receiving items in boxes far larger than necessary, filled with excessive amounts of void fill. This leads to frustration over wasted resources and the inconvenience of disposing of large amounts of packaging. Complaints often focus on the excessive use of non-recyclable plastics, the difficulty of recycling certain packaging components, and the overall feeling of unnecessary waste.

Social media is rife with images of excessively packaged Amazon orders, fueling public criticism and demanding more sustainable practices.

Comparison of Amazon’s Packaging to Competitors, Artificial intelligence cuts down packaging issues for amazon

| Company | Material Used | Packaging Type | Sustainability Initiatives |

|---|---|---|---|

| Amazon | Cardboard, plastic films, paper fillers, tape | Boxes, mailers, polybags | Frustration-Free Packaging, removal of some plastic components, increased use of recycled content |

| Walmart | Cardboard, recycled paper | Boxes, mailers | Focus on reducing packaging size, increased use of recycled content, sustainable sourcing of materials |

| Target | Cardboard, recycled paper, biodegradable fillers | Boxes, mailers, reusable bags (in-store) | Sustainable packaging goals, partnerships with sustainable packaging suppliers |

| Etsy | Recycled cardboard, biodegradable packaging | Boxes, mailers, eco-friendly packaging options | Emphasis on eco-friendly packaging options from sellers, encouragement of sustainable practices |

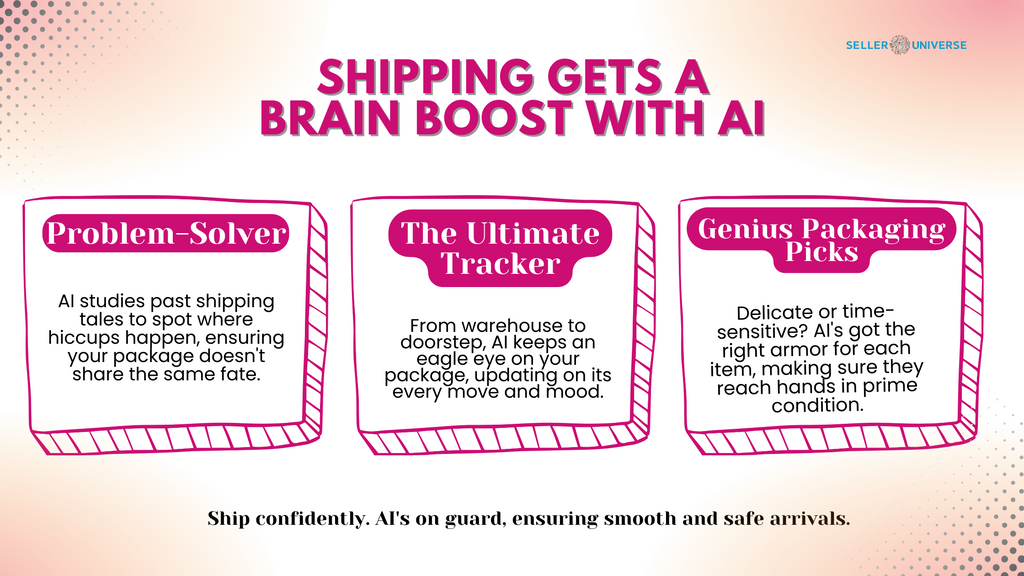

AI-Driven Solutions for Packaging Optimization

Amazon’s massive scale necessitates innovative solutions to its packaging challenges. AI offers a powerful toolkit to optimize every stage of the process, from design to delivery, leading to significant reductions in waste and cost. By leveraging the power of data analysis and predictive modeling, AI can revolutionize how Amazon approaches packaging, making it more sustainable and efficient.AI algorithms can analyze product dimensions and predict optimal packaging sizes with impressive accuracy.

This goes beyond simple measurements; AI considers factors like product fragility, stacking efficiency, and even the specific characteristics of the chosen shipping carrier to determine the most appropriate box size. This prevents the use of oversized boxes, a major contributor to wasted materials and increased shipping costs. The algorithm might consider various box dimensions from a pre-defined library of sizes, selecting the smallest one that meets the protection and shipping requirements.

For instance, an AI could determine that a slightly larger, yet still efficiently sized box, offers better protection for a fragile item, preventing returns and damage claims.

Predictive Modeling for Optimal Packaging Design

Machine learning models can analyze vast datasets of product characteristics, material properties, and past shipping data to improve packaging design. This allows for the creation of custom packaging that minimizes material usage while ensuring sufficient protection during transit. Algorithms can identify optimal materials, thicknesses, and structural designs based on the specific needs of each product. For example, an AI might determine that using corrugated cardboard with a specific flute profile and thickness is the most cost-effective and protective solution for a particular product, rather than relying on a generic, oversized box.

This optimization leads to lower material costs and reduced environmental impact.

AI-Driven Warehouse Logistics for Reduced Packaging Waste

AI plays a crucial role in optimizing warehouse logistics to minimize packaging waste during shipping and handling. By analyzing real-time data on inventory levels, order fulfillment processes, and shipping routes, AI systems can optimize picking and packing procedures, reducing the need for excessive packaging materials. For instance, AI can direct warehouse robots to select the most appropriate packaging size for each order, minimizing the use of void fill materials.

Real-time tracking of packages within the warehouse also allows for the identification of areas where packaging damage is more frequent, allowing for adjustments in handling procedures and potentially the redesign of packaging for those specific items.

Examples of AI-Powered Tools in the Packaging Industry

Several AI-powered tools are already being used in the packaging industry. For example, some companies utilize AI-driven software for automated design generation, allowing for rapid prototyping and testing of different packaging designs. Other tools leverage machine learning to predict and prevent packaging failures, leading to reduced waste and improved product protection. These tools, while not specifically tailored for Amazon, demonstrate the potential for AI to significantly impact packaging optimization across the board.

Imagine an Amazon warehouse utilizing a system that analyzes the fragility of every item and automatically selects the correct packaging and void fill based on the item’s characteristics and destination. This level of automation is achievable with current AI technology. Further, real-time analysis of package handling and shipping data can pinpoint areas for improvement in packaging design or warehouse logistics, creating a feedback loop for continuous optimization.

Implementation of AI in Amazon’s Supply Chain

Integrating artificial intelligence into Amazon’s vast supply chain, specifically targeting packaging optimization, presents a significant opportunity to enhance efficiency, reduce waste, and lower costs. This involves a multifaceted approach, requiring careful consideration of existing infrastructure, technological capabilities, and the overall workflow. Successful implementation hinges on a strategic, phased approach that addresses both the technical and logistical challenges.AI’s role extends beyond simply analyzing existing data; it offers the potential to proactively optimize packaging choices based on real-time demand, product characteristics, and delivery logistics.

This proactive approach is crucial for a company like Amazon, where even minor improvements in packaging efficiency can translate into massive cost savings and environmental benefits.

Potential AI Integration Scenarios in Amazon’s Packaging Processes

Several specific scenarios illustrate how AI could revolutionize Amazon’s packaging operations. AI algorithms can analyze historical sales data, product dimensions, and fragility to predict optimal packaging configurations for each item. This could involve using machine learning models to identify the most efficient box size and type, reducing wasted space and material. Another application involves using computer vision to automate quality control checks, ensuring that packages are properly sealed and labeled, thus minimizing errors and returns.

Finally, predictive modeling could help optimize warehouse layouts and streamline the packaging process, reducing bottlenecks and improving overall throughput. These AI-driven solutions can lead to significant cost savings through reduced material usage and improved efficiency.

Infrastructure and Technological Requirements for AI-Driven Packaging Solutions

Implementing AI-driven packaging solutions requires substantial investment in both infrastructure and technology. This includes robust data storage and processing capabilities to handle the massive datasets generated by Amazon’s operations. High-performance computing resources are essential for training and deploying complex machine learning models. Furthermore, the integration of AI requires sophisticated software systems capable of interacting with existing warehouse management systems (WMS) and order management systems (OMS).

Advanced sensor technology, such as computer vision systems and robotic arms, is necessary for automating tasks like package inspection and packing. Finally, a skilled workforce capable of developing, deploying, and maintaining these AI systems is crucial for long-term success.

Step-by-Step Process for Integrating AI into Amazon’s Packaging Workflow

A phased approach is essential for successfully integrating AI into Amazon’s packaging workflow. Phase 1 involves data collection and analysis, focusing on gathering comprehensive data on product dimensions, material properties, shipping patterns, and customer returns. Phase 2 focuses on model development and training, where machine learning algorithms are trained on the collected data to predict optimal packaging configurations. Phase 3 involves system integration, connecting the AI models with existing warehouse systems and automating packaging processes.

Phase 4 involves testing and deployment, gradually rolling out the AI-driven system across different warehouses and regions. Phase 5 involves continuous monitoring and improvement, using real-time data to refine the AI models and optimize packaging processes further. This iterative approach allows for continuous improvement and adaptation to evolving business needs.

Cost-Benefit Analysis of AI-Based Packaging Solutions

While the initial investment in infrastructure and technology for AI-based packaging solutions is significant, the long-term benefits outweigh the costs. Reduced material usage translates directly into lower procurement costs. Improved efficiency through automation leads to reduced labor costs and faster processing times. Minimized errors and returns reduce operational expenses and improve customer satisfaction. For example, a 10% reduction in packaging material costs for a company like Amazon, with its massive shipping volume, represents a substantial saving.

Furthermore, the environmental benefits, such as reduced waste and carbon emissions, should also be considered. These benefits, when quantified, demonstrate a clear return on investment for AI-driven packaging optimization. Compared to continuing with current methods, the long-term cost savings and improved sustainability make AI-based solutions a compelling strategic choice.

Impact Assessment of AI-Driven Packaging Changes

Amazon’s shift towards AI-driven packaging optimization presents a multifaceted impact, extending beyond mere cost savings to encompass significant environmental and customer experience improvements. This section delves into a detailed assessment of these effects, acknowledging both the benefits and potential challenges.

Environmental Benefits of Reduced Packaging Waste

The environmental advantages of AI-optimized packaging are substantial. By minimizing material usage, Amazon can drastically reduce its contribution to landfill waste. This translates to less deforestation required for raw material production and a decreased need for energy-intensive recycling processes. Furthermore, the reduction in packaging weight leads to lower carbon emissions during transportation, contributing to a smaller carbon footprint across the entire supply chain.

For example, a 10% reduction in packaging weight across millions of shipments annually represents a significant decrease in fuel consumption and associated greenhouse gas emissions. This aligns with Amazon’s public commitments to sustainability and reduces their overall environmental impact.

Cost Savings Associated with Optimized Packaging

AI-driven packaging optimization delivers considerable cost savings for Amazon. Reduced material usage directly translates to lower raw material costs. Moreover, optimized packaging designs lead to improved shipping efficiency. Smaller packages require less space on trucks and planes, resulting in lower transportation costs and increased shipment volume per vehicle. This also reduces fuel consumption and associated expenses, creating a ripple effect of savings throughout the logistics network.

For instance, a hypothetical scenario where Amazon reduces packaging weight by 5% across its shipments could lead to millions of dollars in annual savings due to reduced material and transportation costs.

Challenges in Implementing AI-Driven Packaging Solutions

While the benefits are clear, implementing AI-driven packaging solutions presents certain challenges. Data privacy concerns arise from the collection and analysis of vast amounts of customer data used to optimize packaging. Ensuring compliance with data protection regulations and maintaining customer trust is paramount. Additionally, integrating AI systems into existing supply chain infrastructure can be complex and require significant investment in new technologies and employee training.

Finally, accurately predicting packaging needs and adjusting to fluctuating demand patterns requires sophisticated algorithms and robust data analysis capabilities. For example, unexpected surges in demand might overwhelm the system, potentially leading to temporary inefficiencies until the AI algorithms adapt.

Amazon’s using AI to optimize packaging, reducing waste and shipping costs – a huge win for sustainability! This kind of complex problem-solving is exactly what makes low-code/pro-code development so crucial; check out this article on domino app dev the low code and pro code future to see how these platforms are streamlining app creation for similar logistical challenges.

Ultimately, efficient app development helps companies like Amazon implement and improve AI solutions like their smart packaging system faster.

Impact on Customer Satisfaction

AI-driven packaging improvements positively affect customer satisfaction. Optimized packaging often results in a more pleasant unboxing experience. Smaller, more efficiently designed packaging reduces the amount of excess material, leading to less waste and a more aesthetically pleasing presentation. This contributes to a positive brand perception and enhances customer loyalty. Furthermore, the reduction in packaging waste aligns with growing consumer preference for environmentally friendly practices, further boosting customer satisfaction and reinforcing Amazon’s image as a responsible corporate citizen.

For example, positive customer reviews highlighting the reduced packaging and improved unboxing experience can significantly enhance brand reputation.

Future Trends and Innovations

The integration of AI into sustainable e-commerce packaging is still in its early stages, offering a wealth of untapped potential. As technology advances, we can expect even more sophisticated and impactful solutions to emerge, driving further reductions in waste and environmental impact. This section explores some of the exciting possibilities on the horizon.The synergy between AI and sustainable materials is poised to revolutionize packaging.

AI’s predictive capabilities can be leveraged to optimize the design and use of recycled and biodegradable materials, ensuring both efficiency and environmental responsibility. This goes beyond simply using eco-friendly materials; AI can help determine the optimal blend of materials for specific products and shipping conditions, minimizing material usage while maintaining product protection.

AI-Enhanced Sustainable Material Selection

AI algorithms can analyze vast datasets – including product dimensions, fragility, shipping distances, and environmental impact data for various materials – to select the most suitable recycled or biodegradable packaging for each individual order. For example, an algorithm might determine that a compostable cornstarch-based packaging is appropriate for a lightweight item shipped a short distance, while a recycled cardboard box is better suited for a heavier, more fragile item traveling across the country.

This level of granular control allows for significant reductions in material waste and environmental footprint.

Innovative Packaging Designs Enabled by AI

AI is not only optimizing material selection but also pushing the boundaries of packaging design itself. One exciting area is customizable packaging. Imagine an AI system that designs a uniquely sized and shaped box for each product, eliminating excess void fill and reducing material usage. This dynamic approach could drastically reduce the amount of wasted space in shipping containers.

Another innovation is self-assembling packaging. AI could design flat-pack boxes that automatically fold and assemble themselves upon delivery, removing the need for manual assembly and reducing labor costs while simultaneously using less material than traditional pre-assembled boxes. Companies like Amazon are already exploring similar concepts through patents and R&D.

Future Research Areas in AI and Sustainable Packaging

The potential for AI in sustainable e-commerce packaging is immense, and much remains to be explored. Further research is crucial to fully realize this potential.

- Developing AI models that accurately predict the optimal packaging design for a wide range of products and shipping conditions, accounting for factors like temperature, humidity, and impact forces.

- Improving the accuracy and efficiency of AI-powered material identification and sorting systems for recycling processes, facilitating the use of more recycled content in packaging.

- Investigating the feasibility and cost-effectiveness of using AI to design and manufacture biodegradable packaging materials with enhanced strength and durability.

- Creating AI-driven platforms that allow for real-time monitoring and optimization of packaging throughout the entire supply chain, from design and manufacturing to delivery and disposal.

- Exploring the ethical and societal implications of widespread AI-driven packaging changes, including the potential impact on jobs and the need for transparency and accountability.

Conclusive Thoughts

The integration of AI into Amazon’s packaging process is more than just a technological advancement; it’s a crucial step towards a more sustainable future for e-commerce. By leveraging the power of machine learning and data analysis, Amazon can significantly reduce its environmental footprint while simultaneously boosting efficiency and potentially improving customer satisfaction with more thoughtfully designed packaging. While challenges remain, the potential benefits are undeniable, pointing towards a future where AI plays a pivotal role in responsible packaging across the industry.

It’s exciting to see this technology in action, making a real-world impact on one of the biggest players in online retail.

Q&A

What are the ethical considerations of using AI for packaging optimization?

Ethical concerns include ensuring data privacy related to product information and preventing algorithmic bias that could disproportionately affect certain product categories or suppliers.

How does AI improve the customer unboxing experience?

By reducing excess packaging, AI can lead to a more satisfying unboxing experience, minimizing frustration and waste for the customer.

Could AI-driven packaging solutions be applied to other industries besides e-commerce?

Absolutely! The principles of AI-driven packaging optimization can be applied to various industries, including food and beverage, manufacturing, and pharmaceuticals.

What role do human workers play in this AI-driven system?

Human workers are still crucial for monitoring the system, making adjustments as needed, and handling exceptions or unexpected situations.