Cyber Attack on Iran State TV Shows Dissident Images

Cyber attack on Iran state TV leads to display of images of dissidents – that headline alone speaks volumes! It’s a story that blends cutting-edge technology with deeply rooted political unrest. We’re diving into the technical wizardry behind the hack, exploring the potential motives of the attackers, and examining the powerful symbolism of the images broadcast to millions.

This wasn’t just a technical glitch; it was a bold statement, a digital act of defiance, and a fascinating case study in modern geopolitical warfare.

This incident raises serious questions about Iran’s cybersecurity infrastructure, the capabilities of digital activists, and the evolving landscape of online activism in a highly restrictive environment. We’ll unpack the technical details of the breach, analyze the potential political fallout, and consider the long-term implications for both Iran and the broader international community. Get ready for a deep dive into this captivating story.

The Hack’s Technical Aspects

The successful intrusion into Iranian state television, resulting in the broadcast of dissident imagery, highlights the vulnerability of even seemingly robust systems. This hack likely involved a sophisticated multi-stage process, leveraging several vulnerabilities and exploiting weaknesses in security protocols. Understanding the technical aspects of this operation requires examining the potential methods employed, the vulnerabilities exploited, and the challenges overcome.

Likely Breach Methods

The attackers likely employed a combination of techniques to penetrate Iranian state TV’s security perimeter. Initial access could have been gained through phishing campaigns targeting employees, exploiting known vulnerabilities in outdated software, or leveraging zero-day exploits. Once inside the network, lateral movement would have been crucial to reach the broadcasting systems. This could have involved exploiting vulnerabilities in network devices, such as routers and switches, or compromising privileged accounts with access to critical infrastructure.

The attackers likely used advanced techniques to evade detection, including the use of anonymization tools and custom malware. The Stuxnet attack, for example, demonstrated the power of sophisticated malware to target industrial control systems, providing a relevant precedent for the level of technical expertise required for such an operation.

Exploited Vulnerabilities

Several vulnerabilities could have been exploited. Outdated broadcasting software or operating systems are common targets, often containing known vulnerabilities that haven’t been patched. Network devices, including those managing the broadcast signal, might have lacked proper security configurations, allowing for unauthorized access. Weak or easily guessed passwords, coupled with a lack of multi-factor authentication, could have provided an easy entry point.

Additionally, the absence of robust intrusion detection and prevention systems would have facilitated the attackers’ actions, allowing them to remain undetected for a significant period.

Technical Challenges of Broadcasting Dissident Images

Overcoming the technical challenges of replacing the live broadcast with pre-recorded material required precise timing and a deep understanding of the Iranian state TV’s broadcast infrastructure. The attackers needed to identify the correct control points within the system to inject their content, potentially requiring the manipulation of broadcast servers or direct access to the signal transmission chain. This process would have involved overcoming numerous security measures and protocols designed to prevent unauthorized access and interference.

Successfully replacing the content without causing a noticeable disruption or triggering alerts would have been a major technical feat, demanding precise timing and meticulous planning.

Software and Hardware Used, Cyber attack on iran state tv leads to display of images of dissidents

The attackers likely employed a range of specialized tools and equipment. This might include custom-built malware for initial access and lateral movement within the network, along with tools for privilege escalation and data exfiltration. Software for manipulating broadcast signals and injecting pre-recorded content would have been essential. On the hardware side, the attackers likely used powerful computers for processing and analysis, as well as potentially specialized network equipment to maintain anonymity and evade detection.

Secure communication channels, perhaps using encrypted VPNs, would have been crucial to coordinate the attack and securely transmit data.

Potential Attack Vectors and Effectiveness

| Attack Vector | Target | Effectiveness | Mitigation |

|---|---|---|---|

| Phishing | Employees | High (if successful) | Security awareness training, multi-factor authentication |

| Exploiting Software Vulnerabilities | Outdated software/OS | High (if unpatched) | Regular patching and updates |

| Network Intrusion | Routers, switches | Medium to High (depending on security) | Strong network segmentation, intrusion detection systems |

| Compromising Privileged Accounts | Admin accounts | Very High | Strong password policies, access control lists |

Political and Social Impact

The cyberattack on Iranian state television, resulting in the broadcast of dissident imagery, carries significant political and social ramifications, both immediate and long-term. The incident’s impact extends beyond the technical aspects of the hack itself, reaching into the very fabric of Iranian society and its relationship with the international community. Understanding these consequences requires careful consideration of public reaction, governmental responses, and historical precedent.The short-term impact likely involves increased public unrest and a surge in online activity.

The broadcast of dissident messages, bypassing state censorship, could embolden the opposition and inspire further protests. Conversely, the government might respond with increased internet restrictions and crackdowns on dissent, potentially leading to further societal tensions and a climate of fear. The immediate reaction from the international community will depend on geopolitical factors and the perceived legitimacy of the hack itself; some may condemn the attack as an act of aggression, while others may see it as a form of digital resistance against a repressive regime.

The Iranian state TV hack, broadcasting images of dissidents, highlights the vulnerability of even seemingly secure systems. This incident underscores the critical need for robust security measures, and understanding solutions like bitglass and the rise of cloud security posture management becomes even more crucial. Ultimately, the attack serves as a stark reminder of how easily sensitive information can be compromised if proper security protocols aren’t in place.

Public Opinion in Iran

The display of dissident imagery on state television, a traditionally controlled and trusted source of information, could significantly impact public opinion. For those already sympathetic to the opposition, the hack serves as validation of their beliefs and a demonstration of the regime’s vulnerability. For those who remain loyal to the government, the event might provoke feelings of anger, confusion, and a sense of national humiliation.

The government’s response to the incident – whether it’s a swift crackdown or a more measured approach – will also play a crucial role in shaping public sentiment. The extent of the impact will also depend on the reach and effectiveness of the government’s counter-narrative and propaganda efforts. For example, a similar incident in a different country might see a stronger, more unified public response based on factors such as the country’s overall political climate and level of access to alternative information sources.

Governmental and International Reactions

The Iranian government’s response will likely involve a combination of measures aimed at identifying and punishing those responsible, bolstering its cybersecurity defenses, and suppressing any ensuing dissent. This could include increased surveillance, arrests, and tighter control over media outlets. International reactions will vary based on political alliances and national interests. Countries with close ties to Iran might offer cautious support or remain silent, while others might openly condemn the attack or offer technical assistance to Iran to enhance its cybersecurity capabilities.

The response from international bodies like the UN will likely depend on the political climate and the extent of any physical damage or loss of life resulting from the hack’s consequences. For example, a similar attack on a Western nation might see a more unified and forceful international response, while an attack on a less strategically important nation might result in a more muted reaction.

Comparison with Past Cyberattacks

This incident shares similarities with past cyberattacks targeting state-controlled media, such as the 2010 Stuxnet attack on Iranian nuclear facilities, which although not directly targeting media, impacted the broader narrative and control of information. While the Stuxnet attack focused on industrial control systems, both incidents demonstrate the potential of cyber warfare to disrupt and undermine the power of authoritarian regimes.

The key difference lies in the direct impact on public perception; the broadcasting of dissident images directly challenges the government’s control over information and narrative, unlike the more indirect impact of Stuxnet. The scale and effectiveness of this attack, compared to others, will depend on factors like the duration of the broadcast, the images displayed, and the overall reach of the Iranian state television network.

Hypothetical Escalation Scenario

A hypothetical escalation could involve the Iranian government attributing the attack to a specific nation-state actor, leading to retaliatory cyberattacks or even military actions. The initial hack could spark a wider cyber conflict, with both sides engaging in escalating attacks on critical infrastructure or sensitive data. International condemnation might fail to de-escalate the situation, potentially leading to a broader geopolitical crisis.

The level of escalation would depend on various factors including the perceived threat level by the Iranian government, the international response, and the involvement of other actors. This scenario mirrors the potential for escalation seen in other instances of cyber conflict, such as the ongoing tensions between nation-states in cyberspace. For example, a similar situation involving a major global power could lead to far-reaching economic and political consequences.

The Identity and Motives of the Attackers

The hacking of Iranian state television, resulting in the broadcast of dissident imagery, points to a sophisticated operation with significant planning and resources. Pinpointing the exact perpetrators remains challenging, given the inherent anonymity of the digital realm, but we can explore potential actors and their motivations.The complexity of the attack suggests a group with advanced technical capabilities rather than a lone individual.

Their ability to penetrate Iranian state television’s security systems and seamlessly replace the broadcast signal demonstrates a high level of expertise in network penetration, signal manipulation, and potentially, social engineering.

Potential Attacker Groups

Several groups could be considered as potential perpetrators. These include exiled Iranian dissident groups, foreign intelligence agencies with interests in destabilizing the Iranian regime, or even a loosely affiliated group of hacktivists motivated by ideological or political aims. The lack of a clear claim of responsibility makes definitive attribution difficult. However, examining the nature of the broadcast content—images of dissidents and possibly anti-government messaging—provides clues about potential motivations.

Motivations and Objectives

The primary objective appears to be the dissemination of dissident voices and the undermining of the Iranian government’s control over information. By hijacking a prominent state-controlled media outlet, the attackers sought to reach a wide audience and amplify messages suppressed within Iran. This could be part of a broader strategy to encourage dissent and potentially destabilize the regime.

The choice of state television as a target highlights the symbolic importance of controlling the narrative and the impact of disrupting official messaging.

Resources and Expertise

Executing this type of attack requires a significant investment in resources and expertise. This includes:

- Advanced hacking skills: Expertise in network security, penetration testing, and exploiting vulnerabilities in broadcasting systems.

- Technical infrastructure: Access to powerful servers, sophisticated software tools, and potentially a network of compromised machines for launching the attack.

- Intelligence gathering: Prior knowledge of the Iranian television network’s infrastructure, security protocols, and vulnerabilities would have been essential.

- Financial resources: Funding for equipment, software, and potentially paying for the expertise of skilled hackers.

The level of sophistication suggests a well-funded operation, potentially supported by a state actor or a wealthy organization.

Geopolitical Implications

The identity of the attackers would have significant geopolitical implications. If a foreign intelligence agency is responsible, it could escalate tensions between Iran and that nation. If a dissident group is responsible, it could embolden further opposition within Iran, potentially leading to increased internal unrest. Attribution is critical for understanding the potential fallout. For example, if a Western intelligence agency were implicated, it could lead to international condemnation and retaliatory cyberattacks.

The Iranian state TV hack, broadcasting images of dissidents, highlights the vulnerability of even heavily secured systems. Thinking about building resilient applications? Check out this article on domino app dev the low code and pro code future to see how modern development can improve security and stability. Ultimately, the Iranian incident underscores the need for robust, adaptable systems in the face of increasing cyber threats.

Timeline of the Attack

A plausible timeline might include these stages:

- Intelligence Gathering (Months to Years): Extensive reconnaissance of Iranian state television’s systems, identifying vulnerabilities and weaknesses.

- Vulnerability Exploitation (Weeks to Months): Exploiting discovered vulnerabilities to gain unauthorized access to the network.

- Data Infiltration (Days to Weeks): Uploading the dissident imagery and preparing the replacement broadcast signal.

- Signal Injection (Hours to Days): Overwriting the legitimate broadcast signal with the prepared content at a precisely chosen time.

- Post-Attack Obfuscation (Ongoing): Covering tracks, deleting logs, and potentially employing countermeasures to prevent detection and attribution.

The precision and timing of the attack suggest meticulous planning and coordination over an extended period.

The Imagery and its Significance

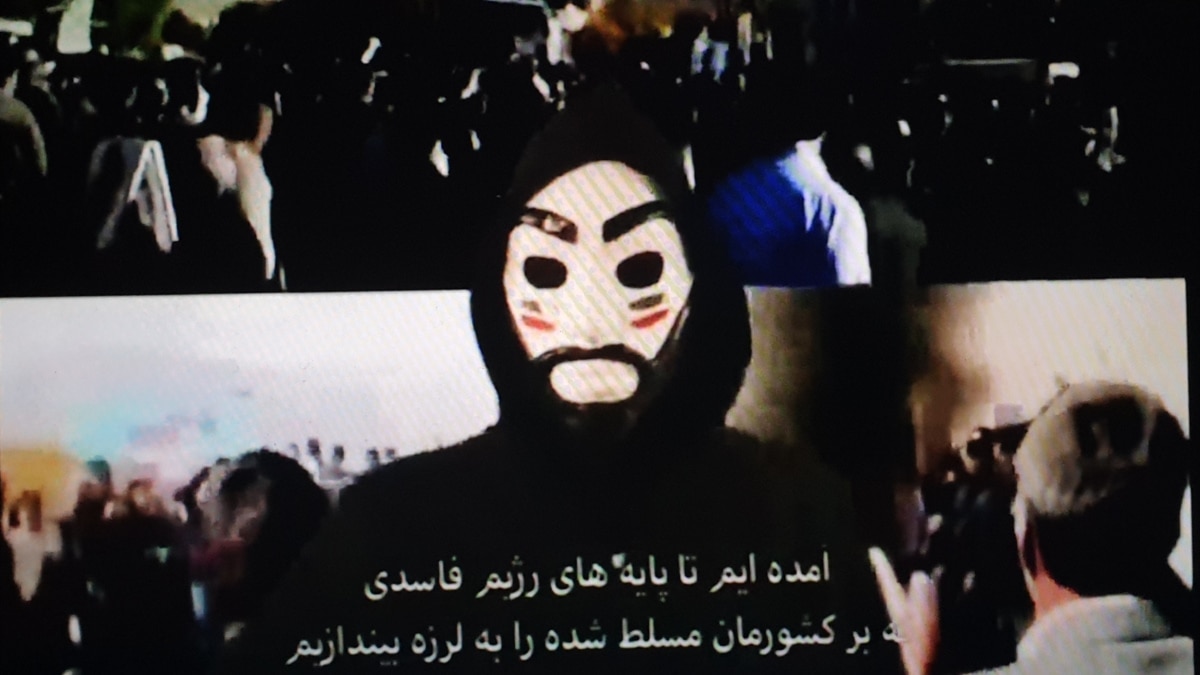

The cyberattack on Iranian state television, resulting in the broadcast of dissident imagery, was far more than a simple technical feat; it was a powerful act of symbolic defiance. The images themselves, carefully selected and strategically deployed, formed a crucial component of the hack’s overall impact, amplifying its message and resonating deeply within Iran’s complex political landscape. The choice of imagery was not arbitrary; it was a calculated move designed to maximize the message’s reach and effectiveness.The selection process of the images likely involved a careful consideration of several factors.

The images displayed were almost certainly chosen for their symbolic power, representing a broad spectrum of dissent within Iranian society. They likely included portraits of individuals who have been imprisoned, killed, or exiled for their activism, religious beliefs, or political views. The selection probably aimed to represent diverse demographics, from ethnic minorities to women’s rights activists, underscoring the widespread nature of opposition to the current regime.

Furthermore, the visual quality and composition of the images would have been considered, ensuring clear visibility and immediate impact on viewers. The attackers likely prioritized images that were easily recognizable and emotionally evocative, capable of triggering strong reactions even amidst the chaos of the interrupted broadcast.

Image Selection and its Impact

The images likely included portraits of prominent figures like Navid Afkari, a wrestler executed for participating in anti-government protests, symbolizing the regime’s brutality. Images of women protesting the mandatory hijab, showcasing their defiance and courage in the face of oppression, might have also been included. The inclusion of images representing various ethnic minorities, such as Kurds or Baluchis, would highlight the diversity of opposition to the regime and challenge the narrative of a monolithic Iranian identity.

The strategic placement and sequencing of these images, even in a short broadcast window, would have aimed to convey a specific message, a visual narrative of resistance.

The Attackers’ Intended Message

Through the broadcast of these images, the attackers aimed to bypass state censorship and directly address the Iranian population. The message was multifaceted: a demonstration of the regime’s vulnerability, a show of solidarity with the dissidents, and a powerful call to action. By broadcasting the faces of those silenced by the regime, the hackers sought to amplify their voices and remind the Iranian people of the ongoing struggle for freedom and human rights.

The message was not just about the act of hacking itself, but about empowering the voiceless and challenging the regime’s control over information.

Imagery vs. Other Forms of Digital Protest

The use of imagery in this context proved far more impactful than other forms of digital protest, such as simple text-based messages or defaced websites. Visuals possess an immediate and visceral impact, capable of bypassing language barriers and resonating on an emotional level. The images, particularly those of victims of state repression, created a powerful emotional response, fostering empathy and solidarity among viewers.

This immediate emotional impact is far more effective in mobilizing public opinion than more abstract forms of digital activism. Consider the impact of a simple text message versus a powerful image of a grieving family – the latter evokes a far stronger emotional response and is more likely to resonate with a wider audience.

Imagery Reflecting Iran’s Political Climate

The imagery broadcast directly reflected the complex and often volatile political climate in Iran. The selection of dissidents, their backgrounds, and the context of their activism provided a visual representation of the various struggles within Iranian society. The images served as a powerful counter-narrative to the regime’s controlled media, showcasing the widespread dissent and challenging the official portrayal of a unified and supportive populace.

The images underscored the ongoing tensions between the government and its citizens, highlighting the deep-seated grievances and the ongoing fight for freedom and human rights. This visual representation provided a stark contrast to the carefully curated image projected by the Iranian state television, effectively exposing the regime’s attempts at suppressing dissent and controlling the narrative.

Cybersecurity Implications and Responses

The Iranian state television hack highlights significant vulnerabilities within Iran’s cybersecurity infrastructure and the broader implications for national security and international relations. The successful intrusion, broadcast disruption, and dissemination of dissident imagery underscore the need for a comprehensive reassessment and strengthening of Iran’s digital defenses. This incident serves as a stark reminder that even state-controlled media organizations, often perceived as highly secure, remain susceptible to sophisticated cyberattacks.The attack’s success exposes weaknesses in Iran’s network security, potentially including insufficient intrusion detection and prevention systems, inadequate employee training on cybersecurity best practices, and a lack of robust incident response planning.

The ability of the attackers to not only breach security but also to maintain control of the broadcast feed for a significant period suggests a sophisticated and well-planned operation, potentially exploiting zero-day vulnerabilities or leveraging insider access. The lack of immediate and effective countermeasures further underscores the need for improved monitoring capabilities and a more proactive approach to threat detection and mitigation.

Iranian Cybersecurity Infrastructure Improvements

Iran needs to invest heavily in upgrading its cybersecurity infrastructure. This includes implementing advanced threat detection and response systems, bolstering network segmentation to limit the impact of breaches, and employing multi-factor authentication across all critical systems. Regular security audits and penetration testing, conducted by independent experts, are crucial for identifying and addressing vulnerabilities before they can be exploited. Furthermore, robust employee training programs focusing on social engineering tactics and phishing awareness are essential to reduce the risk of human error, a common entry point for cyberattacks.

Investment in robust encryption technologies and data loss prevention tools is also paramount. For example, implementing a zero-trust security model, where every user and device is authenticated and authorized before accessing resources, regardless of location, can significantly enhance security. This model was successfully adopted by several large corporations in response to escalating cyber threats.

Improving Cybersecurity in Broadcasting Environments

The broadcasting sector globally faces similar threats. Strengthening cybersecurity in similar environments requires a multi-layered approach. This begins with comprehensive risk assessments to identify vulnerabilities specific to broadcast infrastructure. Robust access control mechanisms, including strong password policies and regular password rotations, are crucial. Network segmentation, isolating sensitive systems from the public internet, is a critical step.

Furthermore, regular software updates and patching are necessary to address known vulnerabilities. The implementation of intrusion detection and prevention systems, coupled with real-time monitoring and analysis of network traffic, is essential for early threat detection. Finally, robust incident response plans, including established communication protocols and pre-defined escalation procedures, are crucial to minimize the impact of successful attacks.

Comprehensive Cybersecurity Strategy for Mitigating Future Risks

A comprehensive cybersecurity strategy for Iran’s broadcasting sector should incorporate the following key elements: A dedicated cybersecurity team with expertise in threat intelligence, incident response, and vulnerability management. A robust cybersecurity policy framework that defines roles, responsibilities, and procedures. Regular security awareness training for all staff, emphasizing best practices and emerging threats. A continuous monitoring and improvement cycle, with regular security audits and penetration testing to identify and address vulnerabilities.

Investment in advanced security technologies, including intrusion detection and prevention systems, firewalls, and data loss prevention tools. A well-defined incident response plan that Artikels procedures for handling cyberattacks, including communication protocols, containment strategies, and recovery procedures. This should include collaboration with international cybersecurity experts for advanced threat intelligence and incident response support. This approach mirrors strategies employed by other nations facing similar threats.

Best Practices for Securing Broadcast Systems

To effectively secure broadcast systems against similar attacks, organizations should adhere to the following best practices:

- Implement robust access control measures, including multi-factor authentication and strong password policies.

- Regularly update and patch all software and hardware components to address known vulnerabilities.

- Segment the network to isolate critical systems from less secure areas.

- Utilize intrusion detection and prevention systems to monitor network traffic for malicious activity.

- Employ robust encryption techniques to protect sensitive data both in transit and at rest.

- Conduct regular security audits and penetration testing to identify and address vulnerabilities.

- Develop and regularly test a comprehensive incident response plan.

- Implement a security awareness training program for all staff.

- Establish strong partnerships with cybersecurity experts and threat intelligence providers.

- Employ data loss prevention (DLP) tools to prevent sensitive information from leaving the network.

Conclusive Thoughts

The cyberattack on Iranian state television, resulting in the broadcast of dissident imagery, serves as a potent reminder of the power of digital activism and the vulnerabilities of even the most tightly controlled systems. The incident highlights the increasingly blurred lines between physical and digital conflict, forcing us to reconsider the implications of both technological advancements and persistent political repression.

The story isn’t over; the ripple effects of this hack will continue to unfold, shaping the digital and political landscape of Iran and beyond for years to come. This incident underscores the need for stronger cybersecurity measures globally and the enduring power of images to ignite change.

Questions and Answers: Cyber Attack On Iran State Tv Leads To Display Of Images Of Dissidents

What specific vulnerabilities were likely exploited in the attack?

While specifics aren’t publicly known, common vulnerabilities in broadcast systems, such as outdated software, weak passwords, and lack of multi-factor authentication, are likely candidates.

Who are the most likely suspects behind the attack?

Attribution is difficult, but various activist groups, both domestic and international, with the technical capabilities to execute such an operation are potential candidates.

What were the long-term consequences of the attack?

Long-term consequences are still unfolding, but they could include increased scrutiny of Iranian cybersecurity, further crackdowns on dissent, and potential escalation of tensions with other nations.

How did this attack compare to previous attacks on state-controlled media?

This attack shares similarities with past attacks on state media outlets in other countries, demonstrating a pattern of using cyberattacks to disrupt information control and amplify dissenting voices.